Update – February 28, 2023: AxCYCLE and AxSTREAM NET are our legacy software packages, replaced by AxSTREAM System Simulation. System Simulation was born out of the union of the legacy AxCYCLE and AxSTREAM NET.

Introduction

Corresponding with the development of industrial technology in the middle of the nineteenth century, people dealt with multiphase flows but the decision to describe them in a rigorous mathematical form was first made only 70 years ago. As the years progressed, development of computers and computation technologies led to the revolution in mathematical modeling of mixing and multiphase flows. There are a few periods, which could describe the development of this computation:

«Empirical Period» (1950-1975)

There were a lot of experiments that were done during this period. All models were obtained from experimental or industrial facilities which is why using them was difficult for different cases.

«Awakening Period» (1975-1985)

Because of sophisticated, expensive, and not universal experiments, the researchers’ attention was directed to the physical processes in multiphase flows.

«Modeling Period» (1985-Present)

Today, the models for multi-flow calculation using the equations of continuity together with equations of energy conservation are obtained, which allow describing phase’s interaction for different flow regimes. (A.V. Babenko, L. B. Korelshtein – Hydraulic calculation two-phase gas-liquid course: modern approach // Calculations and modeling journal. – 2016. – TPА 2 (83) 2016. – P.38-42.)

Technology Development

Since the time of industrial development, installation designs have undergone great changes. For example, there are shell and tube evaporators for freeze systems where the heat transfer coefficient has increased 10 times over during the last 50 years. These results are a consequence of different innovation decisions. Developments led to research into mini-channels systems, which is the one of the methods to increase intensification of phase transition. Research has shown that heat exchange systems with micro and nano dimensions have a much greater effect than the macrosystems with channels dimensions ≤3-200 mm.

In order to organize fundamental research, it is very important to understand hydro, gas dynamics, and heat changes in two-phase systems with the phase transition. At present, the number of researchers using advanced CFD programs has increased. Our team is one of the lead developers of these program complexes.

Mathematical modeling of compressible multiphase fluid flows is interesting with a lot of scientific directions and has big potential for practical use in many different engineering fields. Today it is no secret that environmental issues are some of the most commonly discussed questions in the world. People are trying to reduce the emissions of combustion products. One of the methods to decrease emissions is the organization of an environmentally acceptable process of fuel-burning with reduced yields of nitrogen and sulfur. The last blog (https://blog.softinway.com/en/modern-approach-to-liquid-rocket-engine-development-for-microsatellite-launchers/) discussed numerical methods, which can calculate these tasks with minimal time and cost in CFD applications.

For more effective use of energy resources and low-potential heat utilization, the choice of the Organic Rankine Cycle (ORC) is justified. Due to the fact that heat is used and converted to mechanical work, it is important to use a fluid with a boiling temperature lower than the boiling temperature of water at atmospheric pressure (with working flow-boiling temperature about 100⁰C). The usage of freons and hydrocarbons in these systems makes a solution impossible without taking into account the changes of working fluid phases.

Modeling of the mixing flows and the phase transition is necessary from a microclimate provision, such as conditioning systems (as in an aircraft board), to calculate and design more sophisticated systems. Thus, the design of such a complicated unit as a liquid rocket engine (LRE) is impossible without secondary flows calculation in the turbopump where two fuels such as fuel and oxidizer could be simultaneously compressed. Due to the structural imperfections of the equipment, danger of fuel component leakages through seals always exist which can lead to mixing of them. This is unacceptable. In this case, the third neutral component could be added in the mixing zone, which prevents oxidizer and fuel to mix with each other and thus creates a buffer zone.

Speaking of LREs, it must be emphasized that the nozzle has very big thermal gradients along the walls, and it is important to organize its efficient cooling. In some cases, it also needs to have a process cooling system model with the phase transition in the channels. Due to the influence of high temperatures it is transfering from the liquid to the gas state, hydrogen can be used as a cooling fluid (for example RS-25 SSME). This possibility needs to be estimated.

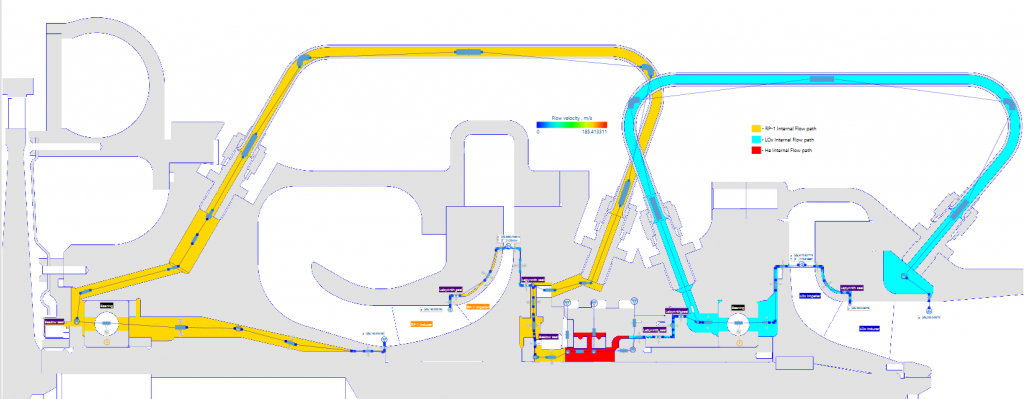

As seen, each case has different sophisticated goals, which are necessary to solve. As technology continues to advance, analysis software such as AxSTREAM NET™, allows researchers to solve issues in many industrial engineering applications. If you would like to learn more about modern applications for multiphase flow calculations, please contact the SoftInWay team or check out our on-demand webinar, Modeling and Analysis of Multiphase Flow Systems!