Anti-Icing System Modeling and Simulation for Gas Turbines

Anti-icing systems are used in aviation and on ground gas turbines in conditions of high humidity and low temperature. In such inclement weather, ice can form in the air intake and on the blades of the initial stages of the compressor. This ice disrupts compressor function in two ways: creating excessive vibration, or surging by decreasing the inlet flow. In these cases, an anti-icing system is employed which heats the inlet air before it reaches the compressor.

Implementation of an anti-icing systems has a significant impact on the efficiency of the entire cycle. Therefore, it is extremely important during the design or modernization of such systems to:

- Assess possible introduction methods for the anti-icing systems into the gas turbine cycle and choose the best option

- Accurately analyze the hydraulics of the bypass pipeline to avoid choking, or insufficient air flow to the anti-icing system

- Analyze possible gas turbine operating scenarios for the anti-icing system and evaluate the efficiencies of each.

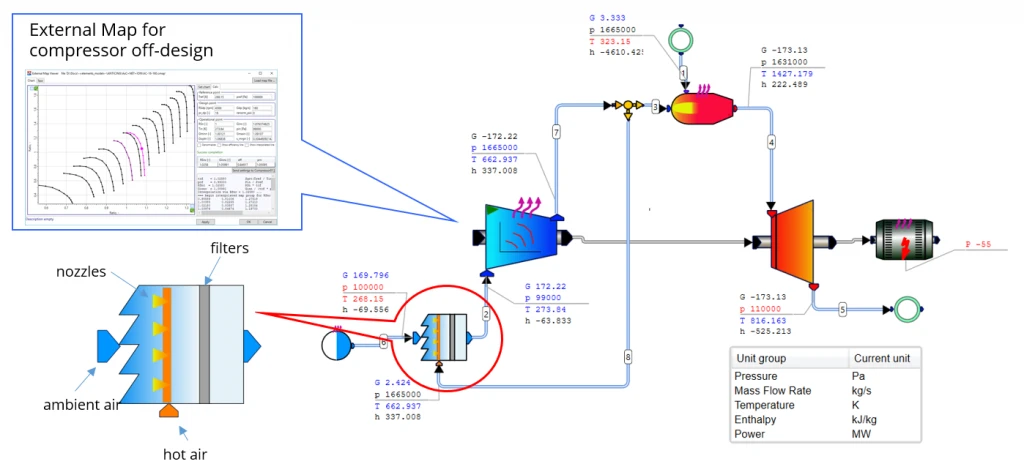

SoftInWay has developed a software solution to jointly solve the problems of constructing an optimal cycle and designing a bypass pipeline. AxCYCLE™ allow users to easily determine the air flow rate to the anti-icing systems in order to prevent ice formation.

Major factors that contribute to potential ice formation are dew point, humidity, pressure and velocity. Dew point of the heated air depends on many factors such as humidity and water content in the ambient air and humidity of the mixed air. It is, however, more important to account for the humidity of the exhaust flue gases because they contain significantly more moisture than the ambient air. The pressure and the velocity of the mixture at the inlet to the compressor is also critical. Higher speeds and lower pressures create a higher possibility of ice formation. AxCYCLE™ allows users to automatically take into account the changes in these important factors in different operating modes. Users can create accurate hydraulic calculations of the bypass pipeline in AxSTREAM NET™, and the results can be transferred seamlessly to AxCYCLE where along with the analysis of the cycle, users can simulate accurate behavior of the entire system in any operating mode.

In this webinar we will discuss how to design the most optimal anti-icing system, while ensuring high gas turbine efficiency in all operating modes. Practical examples and case studies will be demonstrated throughout the presentation.

The webinar session will include:

- Overview of possible scenarios for using an anti-icing system in gas turbine design and the principles of anti-icing system simulation.

- Overview of the capabilities for bypass pipeline hydraulic network simulation and analysis

- Demonstration of a gas turbine thermodynamic cycle in AxCYCLE™ and a hydraulic bypass network in AxSTREAM NET™, with data transfer between the two platforms for joint analysis.

- Results of these systems in operation and their analysis in different operating modes.

Who should attend:

- Engineers, managers, and supervisors who want an introduction on how to design and analyze thermodynamic cycles and thermal-fluid networks.

- Engineering professionals working with gas turbine systems.

- Engineering students looking to expand their knowledge of thermodynamic cycles and thermal-fluid flow simulation.

Simulating Advanced Data Center Cooling Systems with AxSTREAM

View Details

Holistic Turbofan Design & Optimization with AxSTREAM

View Details

Solving Simulation Challenges in Advanced Propulsion Systems

View Details