Design and Analysis of Aircraft Environmental Control Systems Coupled with Engine Propulsion Cycles

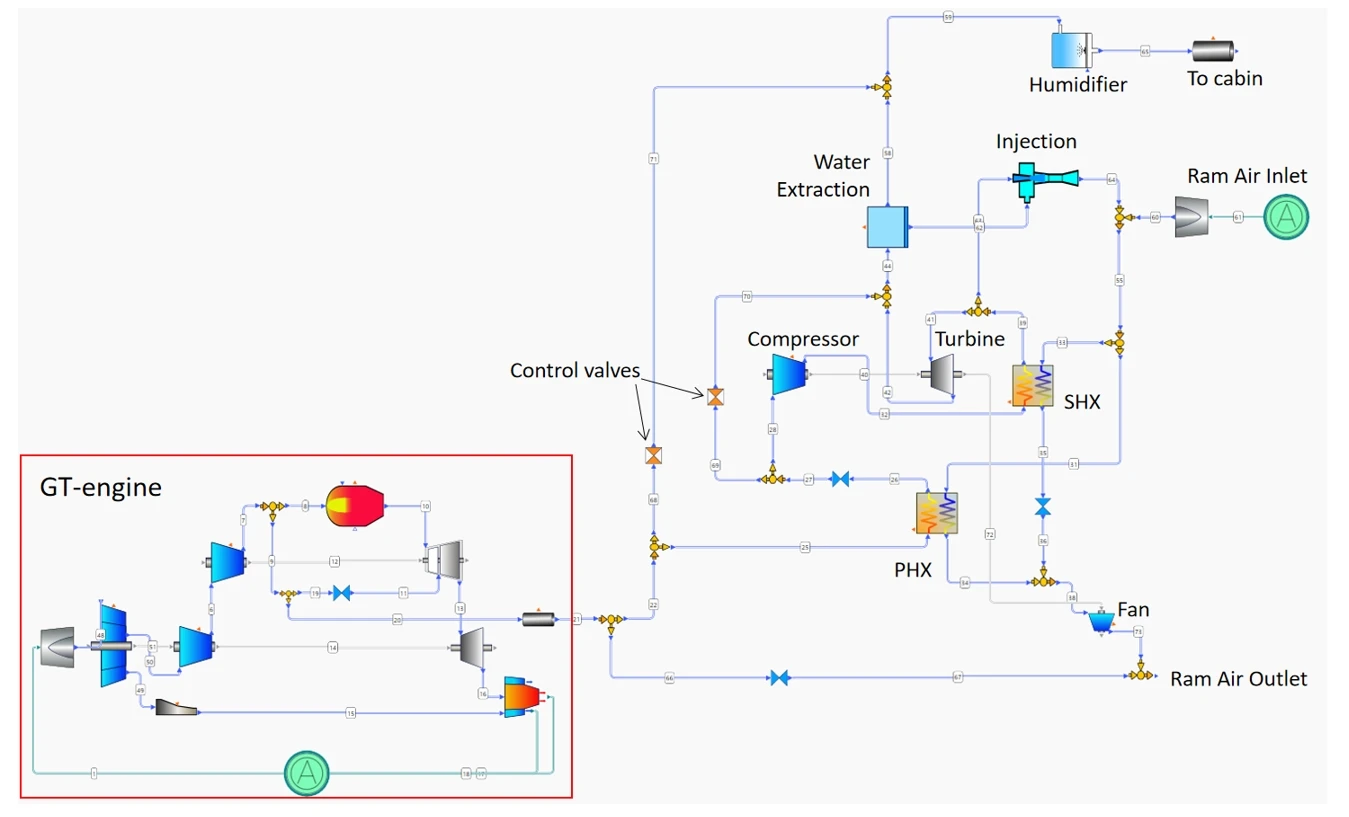

Environmental control systems (ECS) are a necessity to ensure occupants health, safety and comfort as well as maintain equipment (sensors, avionics, etc.) safe temperatures and humidity throughout commercial and military flights. However, nearly all environment control systems require bleed air from the aircraft engine which often negatively affects the engine’s thrust performance. This, in turn, results in higher fuel consumption, especially as recent trends draw more power and thermal resources from this critical system. On the other side of the coin, electrical motor-driven environmental control systems are being explored to reduce that pneumatic power need in favor of secondary electrical power. Regardless of the type of ECS however, they all come with their own trade-offs in terms of weight, cost, complexity, and reliability, which is important to understand before committing to one configuration or approach. This is one of the many ways digital engineering, here through 0D-1D reduced order system modelling, can offer value, as it enables companies to easily and quickly estimate and weigh cabin comfort requirements against bleed air requirements (and corresponding engine performance) and the aforementioned metrics.

In this webinar, we will start by presenting how to simulate traditional environmental control systems before looking at alternatives with the goal to explore methods and strategies to quickly and accurately compare aircraft ECS and understand their tight integration (or lack thereof) with the engine through coupled and decoupled system modeling. This modern steady-state and transient ready 0D-1D approach enables digital prototyping which reduces the extent and costs of physical testing without compromising quality. By bringing together system-level thermodynamics design/analysis (cycles) and 1D thermal fluid network (secondary flow) modeling early in the development process, companies can significantly decrease the time and resources required to design ECS, without adversely affecting performance predictions. This will also be the first look at our new AxSTREAM NET software, which brings together legacy 0D and 1D solvers into a new and intuitive interface for a powerful solution.

The topics covered in this webinar include:

- Overview of aircraft environmental control systems, their challenges and existing solutions

- Advantages of coupled 0D-1D analysis of aircraft engine and environmental control system to identify strengths and weaknesses of different ECS solutions

- Practical example and results of modeling coupled and decoupled ECS

Who should attend?

- Engineers involved in propulsion and auxiliary systems design (including but not limited to gas turbine cooling, anti-icing system, pneumatic system, etc.)

- Engineers who are looking for easy, fast and reliable tools to model systems at different levels of fidelity and integration

- Engineering managers interested in reducing project lead time and resources through digital engineering

- Engineering students looking to better understand interactions between propulsion and auxiliary systems across aerospace and other industries

Simulating Advanced Data Center Cooling Systems with AxSTREAM

View Details

Holistic Turbofan Design & Optimization with AxSTREAM

View Details

Solving Simulation Challenges in Advanced Propulsion Systems

View Details