Automatic Design of Centrifugal Compressors in Fuel Cell Systems

With pressure on the automotive and transportation industries to reach various zero-emission targets, and lower global dependence on fossil-fuels, electric alternatives utilizing fuel cell systems are picking up speed to provide a renewable and carbon-neutral path forward.

Polymer electrolyte membrane (PEM) fuel cells utilize the electrochemical reaction of hydrogen and oxygen to produce electricity with water as a byproduct. Because of its low temperature working conditions and high efficiency, the PEM fuel cell has gotten the attention of organizations both large and small, especially in the automotive and aviation industries.

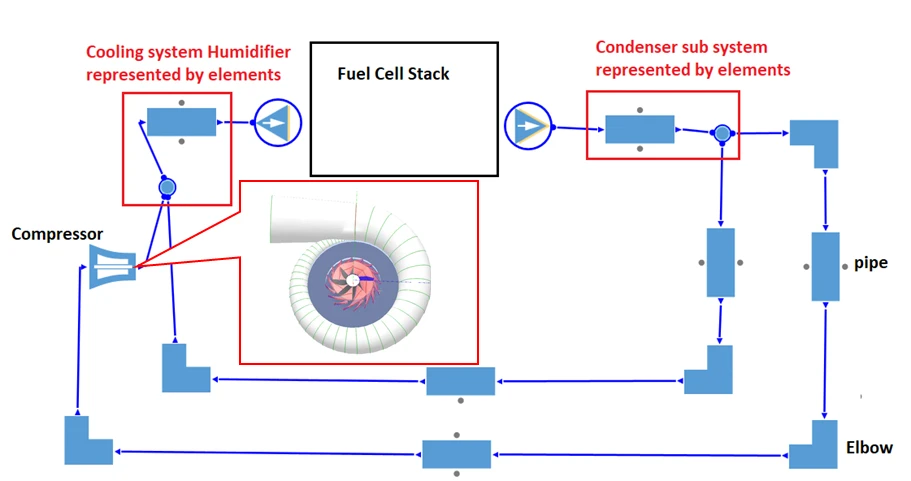

Fuel cell system units can be divided into four subsystems, which consist of a fuel cell stack, air supply subsystem, hydrogen supply subsystem, and water/thermal management subsystem. The air supply subsystem consists of a compressor driven by an electrical motor, humidifier, an air filter, air cooler, and an optional expander for added energy recovery. The compressor is the centerpiece of the air supply system, pressurizing the ambient air to the optimum operating pressure for the fuel cell stack and providing the required air mass flow depending on the electrical power demand of the entire system.

In this webinar, we will focus on the design of a centrifugal compressor for optimum fuel cell operation. By having an accurate performance map for the centrifugal compressor and knowing the characteristics of the fuel cell, we can evaluate their joint work. This will enable us to design the optimal compressor for maximum efficiency and overall system performance. The process will be automated through AxSTREAM ION, which will link data transfer between multiple disciplines and operating points, significantly speeding up the design process while achieving optimum system-level design.

Throughout this webinar session we will:

- Establish centrifugal compressor design constraints and boundary conditions

- Set up the development workflow utilizing process automation to accelerate the design process

- Execute the workflow utilizing AxSTREAM ION

- Analyze the results obtained from AxSTREAM ION

- Demonstrate the performance of the fuel cell and centrifugal compressor system

Who should attend?

- Fuel cell systems engineers (thermodynamics engineers), system simulation engineers, PEM fuel cell engineers, and automotive engineers

- Centrifugal compressor design engineers looking to improve their workflow

- Managers who would like to expand their knowledge about the capabilities of modern design tools for compressors.

- Students who are thinking of careers in turbomachinery engineering and would like to learn the fundamentals of compressor design within a fuel cell system.

- University faculty members who specialize in turbomachinery and fuel cell systems.

Simulating Advanced Data Center Cooling Systems with AxSTREAM

View Details

Holistic Turbofan Design & Optimization with AxSTREAM

View Details

Solving Simulation Challenges in Advanced Propulsion Systems

View Details