SIMCENTER 3D

Advanced Structural Simulation for Optimizing Product Performance

Simcenter 3D is an advanced structural, thermal, and motion simulation platform that enables engineers to evaluate and optimize product performance using high-fidelity analysis. As mechanical systems grow more complex and development timelines shrink, engineering teams often rely on disconnected tools, manual geometry preparation, and repetitive model updates that slow progress. Simcenter 3D addresses these challenges by providing a unified environment for preparing simulation models, running advanced solvers, and managing analysis data, resulting in faster and more reliable structural and mechanical evaluations.

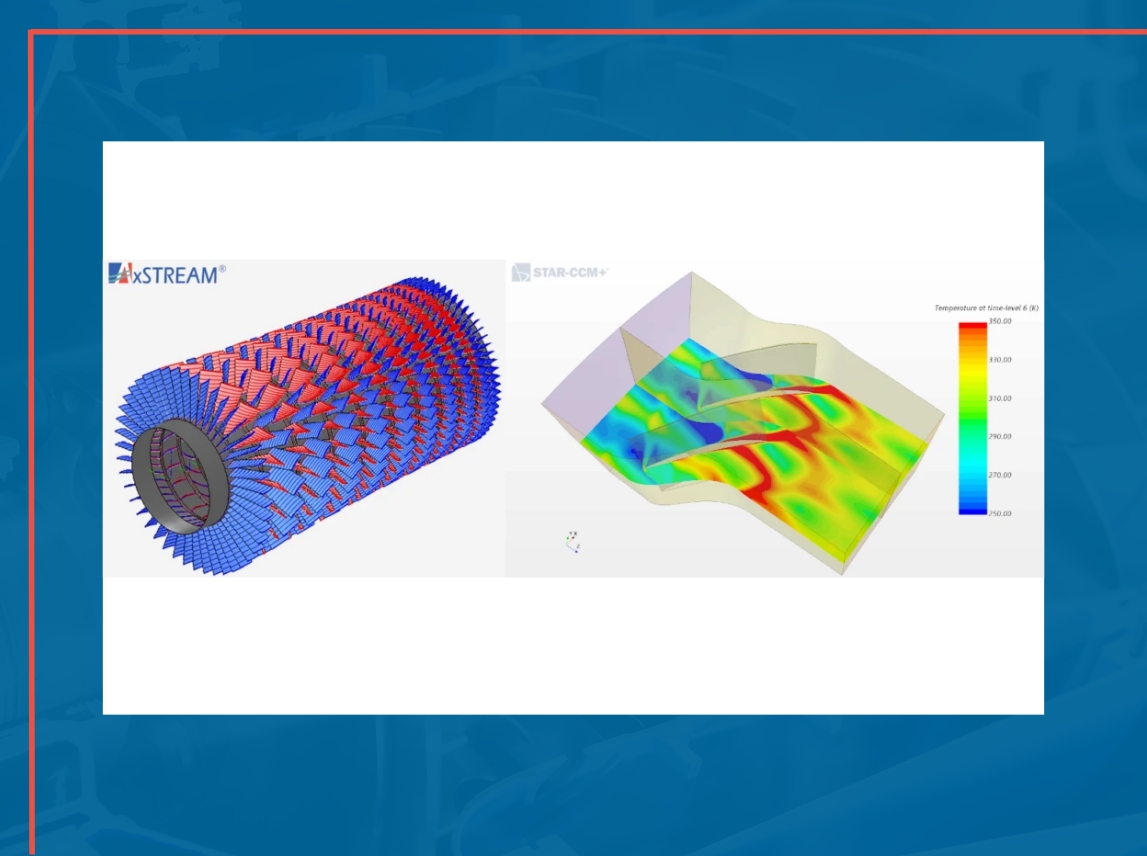

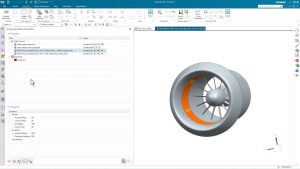

With AxSTREAM, teams can seamlessly transfer turbomachinery geometries, loading conditions, and early-stage design parameters into Simcenter 3D, enabling detailed stress, vibration, thermal, fatigue, and motion analysis. This integrated workflow supports turbomachinery, aerospace, automotive, energy, and industrial applications, delivering earlier insight into structural reliability, product behavior, and overall performance.

Simcenter 3D Benefits & Capabilities

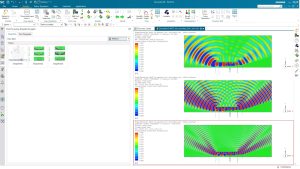

Geometry Preparation, Meshing & Simulation Automation

Benefits:

- Accelerate model preparation with CAD-linked geometry tools that reduce manual rework and maintain consistency across design updates.

- Improve simulation accuracy with high-quality automated adaptive meshing, leveraging the NX feature tree to precisely control mesh density on critical geometry features.

- Increase consistency across teams by capturing repeatable setup steps through templates and lightweight scripts.

- Lower cost and minimize errors by reducing repetitive geometry preparation and solver setup tasks

Capabilities:

- Prepare simulation-ready models with direct modeling, defeaturing, midsurfacing, and geometry healing tools.

- Generate automated, adaptive, parameter-driven meshes for complex components and large assemblies.

- Maintain associative links to CAD for rapid updates and design changes.

- Capture recurring workflows through templates, scripts, and controlled simulation processes for consistent analysis across product iterations.

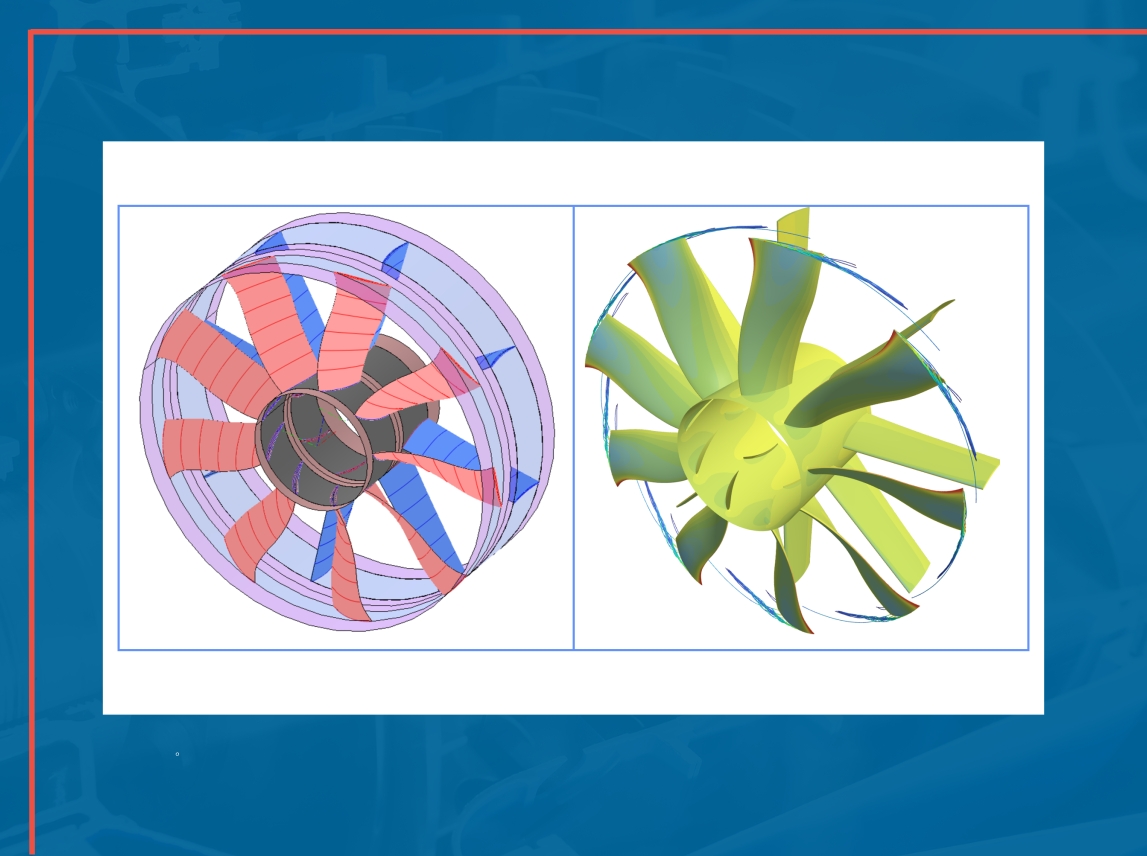

- Import AxSTREAM-generated turbomachinery geometry into Simcenter 3D to accelerate geometry creation and preparation for downstream simulation.

Structural, Motion & Mechanical Simulation

Benefits:

- Eliminate data loss and inconsistencies by evaluating structural, thermal, and motion behavior within a single unified environment.

- Accurately predict structural and mechanical behavior using validated, industry-proven solvers.

- Reduce setup effort through associative CAD-linked simulation workflows.

- Predict real-world performance

- Accelerate design cycles by evaluating stress, vibration, fatigue, acoustics, thermal response, electromagnetic effects, and making corresponding design changes in one integrated platform.

Capabilities:

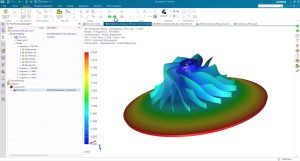

- Run simulations encompassing linear and nonlinear stress, thermal response, motion, vibration, acoustics, fatigue, and electromagnetic behavior.

- Perform nonlinear static and dynamic analysis with multi-step loading, material nonlinearity, contact modeling, and failure prediction.

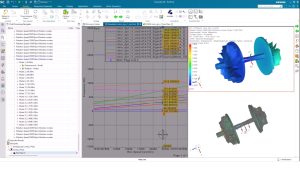

- Analyze rigid and flexible multibody systems with co-simulation across mechanical components.

- Evaluate noise, vibration, and harshness, fatigue life, and durability within integrated workflows.

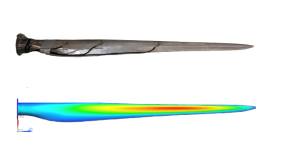

- Validate AxSTREAM-defined blade rows, rotors, and other structural components through detailed modal, harmonic, and fatigue analyses.

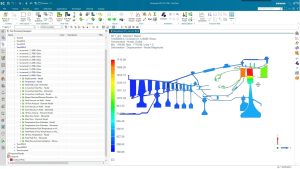

Digital Thread & Data Management

Benefits:

- Keep simulation aligned with design and product development processes throughout the lifecycle.

- Enhance collaboration through full traceability across teams, projects, model revisions, and analysis disciplines.

- Improve decision-making by enabling reuse of validated simulation data and eliminating redundant work.

Capabilities:

- Connect 3D structural simulation models to the broader digital thread spanning CAD, 1D system simulation, test data, and downstream manufacturing workflows.

- Manage simulation files, revisions, assemblies, material models, and analysis setups across global engineering teams.

- Support co-simulation with system models, thermal tools, motion solvers, and physical test data for correlation and validation.

- Integrate with Teamcenter to strengthen simulation data governance and traceability at the enterprise level.

- Link AxSTREAM parameters and simulation results into PLM environments to ensure accuracy and consistency in turbomachinery development.

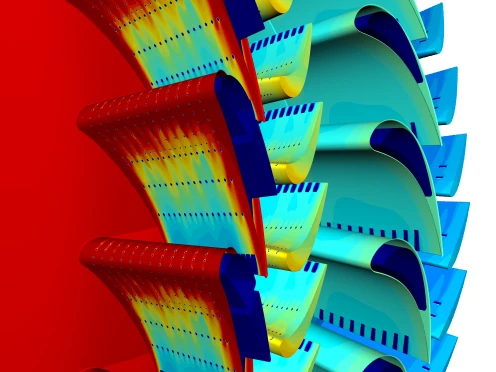

Materials, Manufacturing & Additive Processes

Benefits:

- Improve simulation accuracy by modeling true material behavior and manufacturing influences early in the design cycle.

- Avoid costly redesigns by identifying distortions, residual stresses, and manufacturability challenges before production.

- Shorten composite development cycles with integrated laminate design, draping, and failure analysis.

- Strengthen structural integrity by evaluating residual stresses and manufacturing-induced defects.

- Enhance long-term durability by simulating production-related effects and lifecycle conditions.

Capabilities:

- Model advanced materials including composites, plastics, metals, foams, and multi-material structures with high-fidelity constitutive behavior.

- Define laminate sequences, simulate draping, and apply composite strength and failure criteria.

- Simulate metal and polymer additive manufacturing, including distortion prediction and compensation.

- Analyze manufacturing effects from welding, forming, and forging to understand their impact on product performance.

- Validate manufacturability of AxSTREAM-generated turbomachinery components by assessing forming, forging, and additive feasibility within Simcenter 3D.