NX CAD

Powerful 3D Product Modeling for Production-Ready Designs

NX CAD is a robust 3D product modeling platform that enables engineers to create precise, manufacturable components and assemblies. As products grow more complex and development timelines shrink, teams need tools that can handle intricate geometry, preserve design intent, and support the creation of reliable mechanical systems. NX CAD provides this foundation by enabling engineers to shape detailed models, organize complete assemblies, and produce the documentation required for manufacturing.

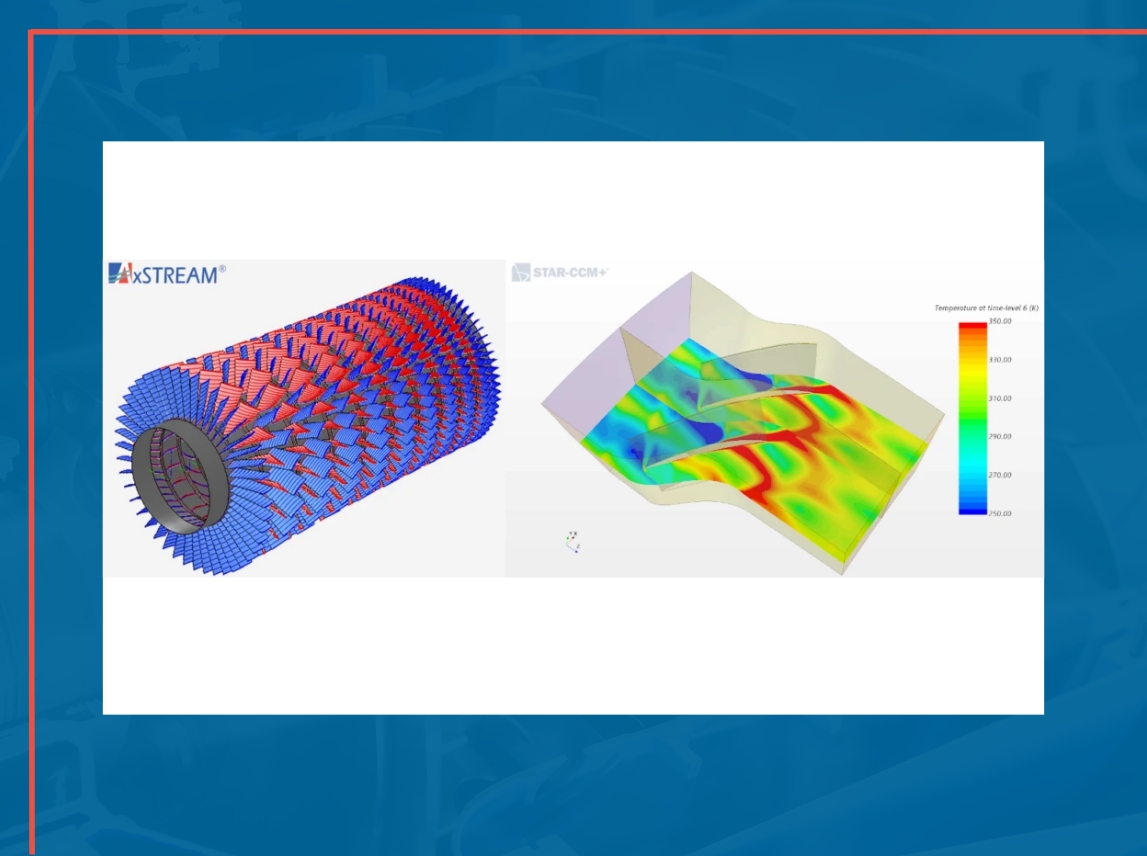

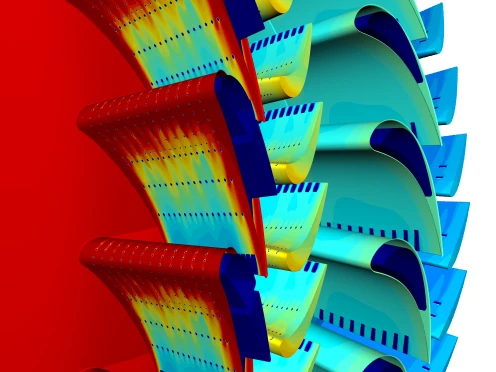

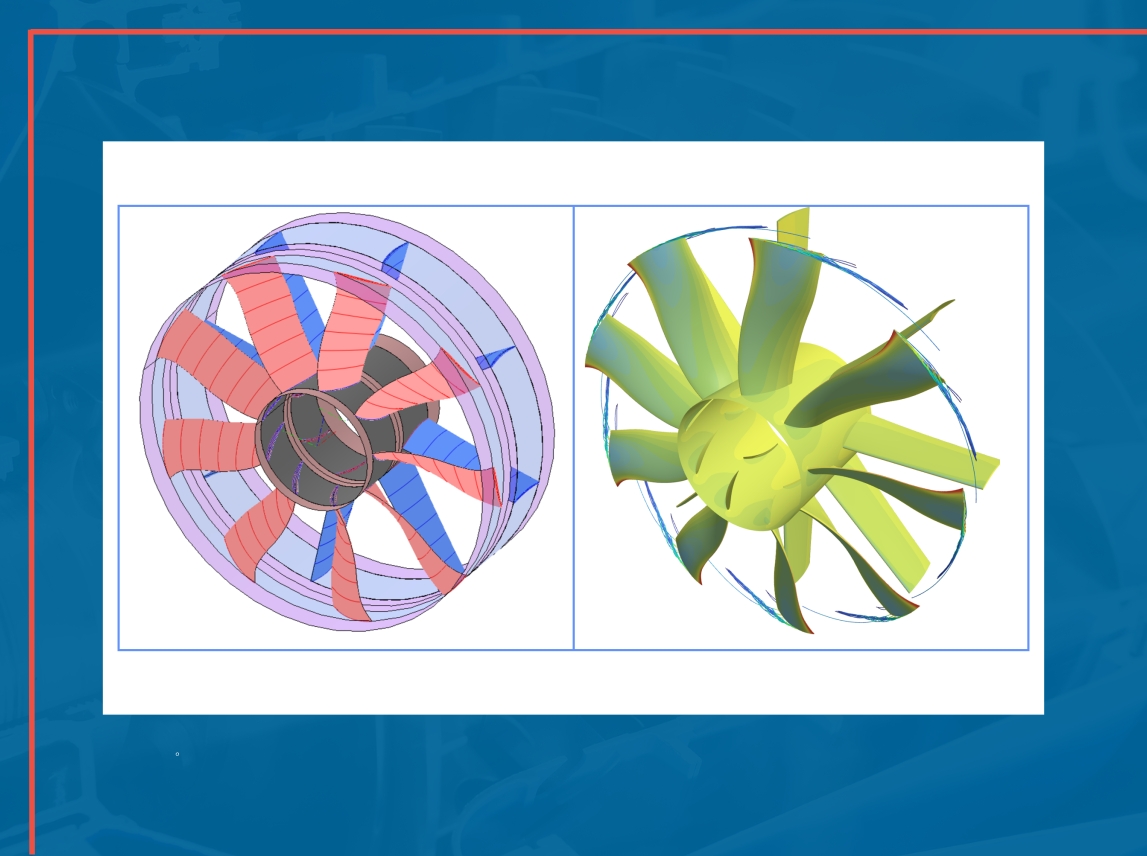

When connected with AxSTREAM, turbomachinery designers can transition directly from aerodynamic or thermodynamic design into production-ready geometry in NX CAD. AxSTREAM defines the turbomachinery design intent and core geometry, while NX CAD refines these components for manufacturing and integrates them into the full product assembly. This creates a seamless workflow from preliminary design to fully realized CAD.

NX CAD Capabilities & Benefits

Advanced 3D Modeling and Assembly

Benefits:

- Develop precise and manufacturable 3D component models that help engineers identify geometry issues early in the design process.

- Verify system-level fit, alignment, and mechanical relationships by assembling components digitally before entering manufacturing.

Capabilities:

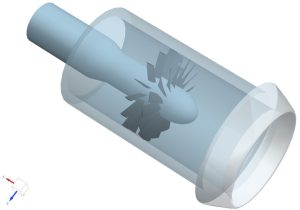

- Create detailed 3D components using parametric modeling, freeform modeling, surface modeling, and synchronous technology.

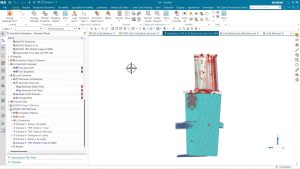

- Construct full assemblies to analyze relationships between components, check clearances, and verify that parts fit and function as intended.

- Apply advanced modeling features such as blends, ribs, patterns, and complex surfaces to meet engineering and manufacturing requirements.

- Integrate AxSTREAM turbomachinery components into assemblies to validate packaging, mechanical interfaces, and spatial constraints.

2D Modeling , Seamless CAD Import, and Assembly

Benefits:

- Accelerate early design exploration by using 2D layouts to define and evaluate concepts before developing detailed 3D models.

- Reduce reconstruction time by bringing in existing CAD files and templates rather than recreating geometry manually.

Capabilities:

- Create sketches and profiles that can be refined and transformed into 3D geometry.

- Import CAD data from other design tools or bring in AxSTREAM-generated turbomachinery geometry to support efficient model development, assembly placement, and integration studies.

- Build assemblies by positioning and managing components within larger product structures.

Documentation, Drafting, and Customization

Benefits:

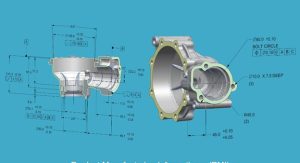

- Improve communication across engineering and manufacturing teams with clear, accurate drawings and documentation that preserve design intent.

- Support efficient handoff to production by generating detailed specifications that reduce ambiguity and prevent rework.

- Increase productivity through customization options that allow teams to streamline repeated tasks and adapt workflows to their specific needs.

Capabilities:

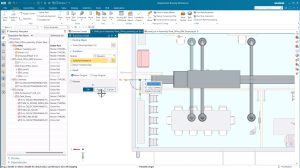

- Produce 2D drawings and engineering documentation with dimensions, annotations, tolerances, and bills of materials.

- Transfer data reliably across design stages to maintain consistency as products move toward manufacturing.

- Automate repetitive tasks with custom features, macros, scripts, and plugins tailored to individual user or company requirements.

- Reference geometry and technical details from AxSTREAM to ensure that manufacturing documentation stays aligned with turbomachinery design parameters.