![]() Dec 4, 2025

Dec 4, 2025

Electrolyzers in Practice: Schemes and Applications

Today, electrolyzers are widely used to produce clean fuel, known as green hydrogen, and are a promising technology for sustainable energy development. In practice, electrolyzers are integrated into complex energy systems that don’t just produce green hydrogen but also store it for later use. Let’s explore real-life applications of electrolyzers and see how AxSTREAM System Simulation can model their integration into energy systems.

Integrating Electrolyzers into Energy Systems

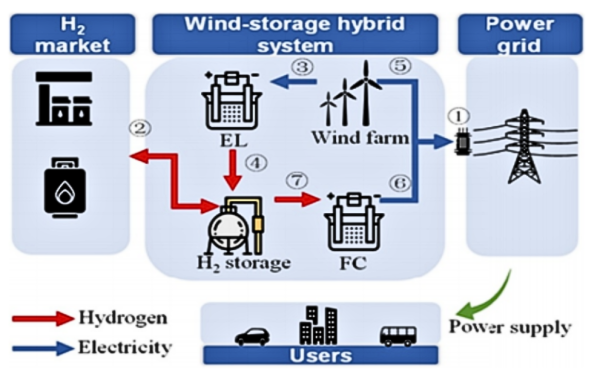

During times of high energy demand, hydrogen produced through electrolysis can be stored in pressurized tanks, or in the form of chemical compounds like ammonia and methanol. This stored hydrogen can be used whenever it’s needed. When hydrogen is supplied to the fuel cell, an electrochemical oxidation reaction takes place, creating electrical and thermal energy, which can be used to power various facilities or fed into the power grid.

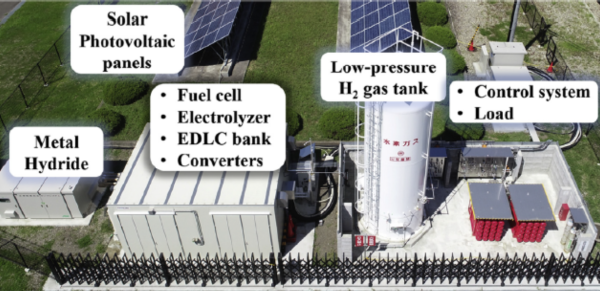

Electrolyzers are often used in systems that utilize power from renewable resources, like solar panels and wind farms, and convert excess electricity generated during peak production into hydrogen that can be stored for subsequent use.

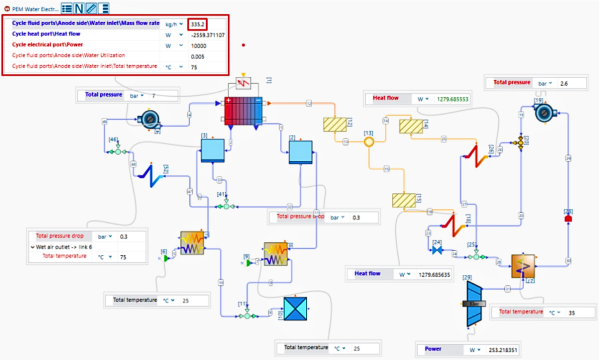

Fig 1. View of the model system

Since not every day brings the same amount of wind or sun, renewable energy can be unpredictable. So, electrolyzers don’t always get a steady supply of electricity. That’s why buffer storage systems and clever load management are needed to keep them running smoothly.

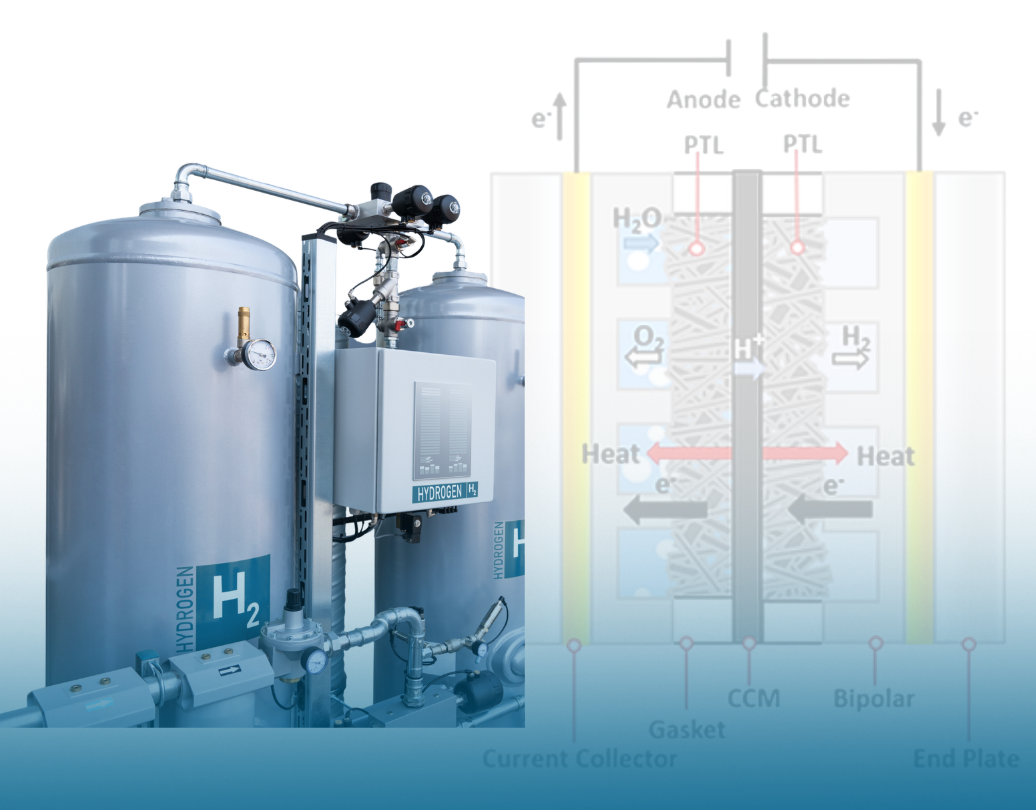

As touched on in our previous blog, the most common types of electrolyzers are Proton Exchange Membrane (PEM) and Solid Oxide (SOE), which are distinguished by their high efficiency, compactness, and ability to be integrated into energy systems that use renewable energy sources. Let’s take a closer look at how they work.

Fig 2. Diagram of wind storage hybrid system

Proton Exchange Membrane (PEM) Electrolyzer Integration

PEM electrolyzers are known for their rapid response to changes in electrical load and their compact design. Since they have high dynamic flexibility and can work under variable load conditions, they’re very effective when operating with unpredictable energy sources like solar and wind [9]. Take a look at a system with an integrated PEM electrolyzer in Figure 3.

Fig 3. Energy cycle diagram in AxSTREAM System Simulation with integrated PEM electrolyzer

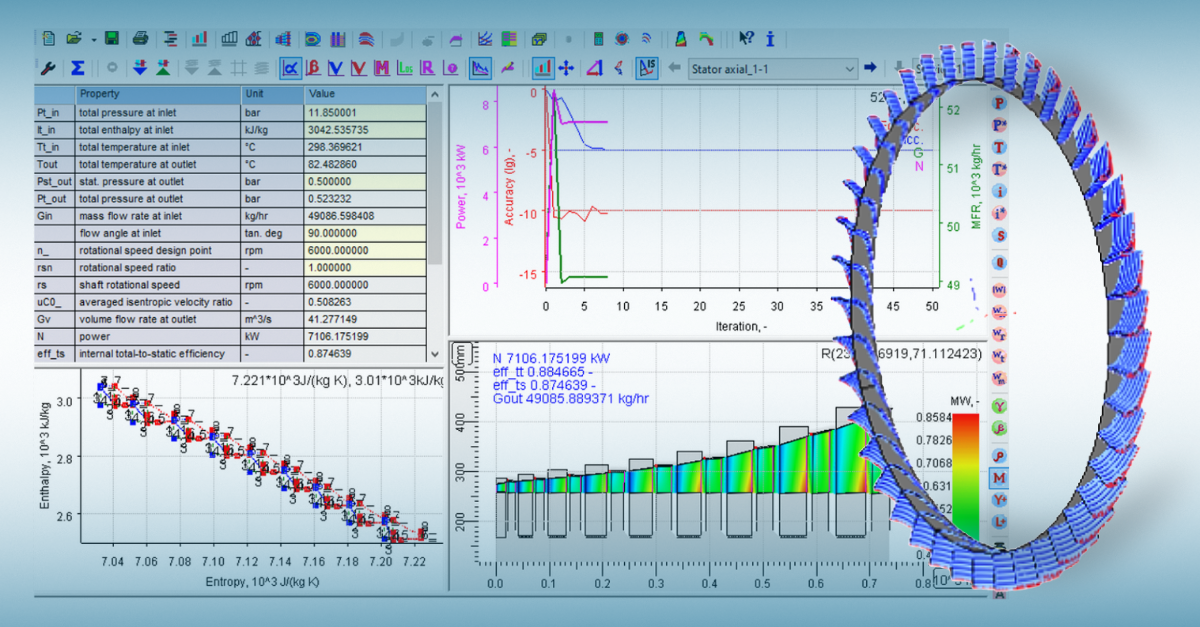

When performing thermodynamic modeling of these systems, it’s important to accurately represent the electrolyzer’s operating characteristics, including the distribution of hydrogen and oxygen flows, electrical power consumption, heat losses, and the influence of load changes on the stability and efficiency of the process. It is also essential that the model assesses energy losses, flow balance, and the potential for heat recovery within the overall energy system.

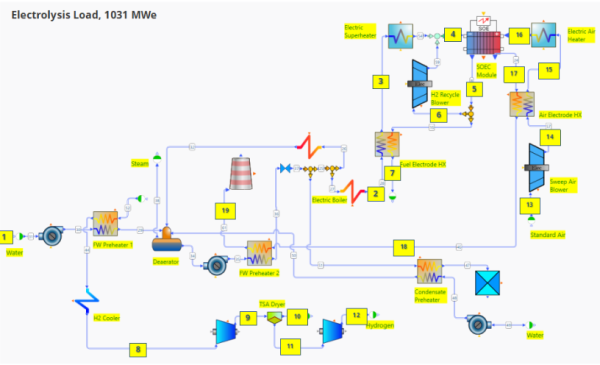

Solid Oxide (SOE) Electrolyzer Integration

SOE electrolyzers offer higher energy conversion efficiency thanks to their high operating temperatures (700–850 °C). They also utilize waste heat from auxiliary processes, making them particularly promising for integration into industrial and cogeneration systems.

Figure 4 shows a schematic of an energy cycle that integrates a SOE electrolyzer with an installed capacity of 1031 MW. This model, developed in the AxSTREAM System Simulation environment, was based on the configuration and parameters from a U.S. National Energy Technology Laboratory (NETL) project [10].

Fig 4. Energy cycle in AxSTREAM System Simulation with SOE electrolyzer integration

This model makes it possible to analyze how various electrolyzer parameters and external conditions affect the overall system while also identifying potential opportunities to improve its energy performance.

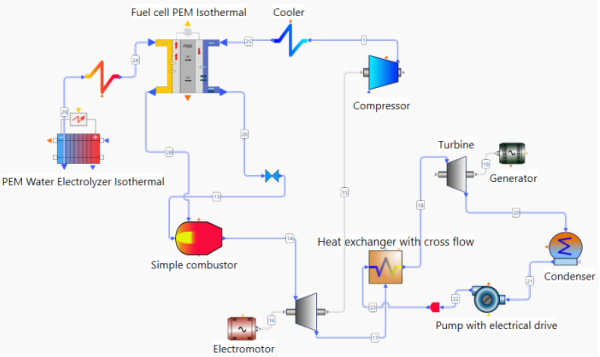

The Role of Fuel Cells in Electrolyzers

To make the most of the hydrogen produced by electrolysis, optimized systems for its storage and subsequent energy conversion are essential. Fuel cells play a central role in this process as they convert hydrogen back into electricity. By integrating fuel cells into the energy cycle, closed hydrogen loops can form, which enhance the system’s flexibility and reliability while ensuring a sustainable balance between energy generation, storage, and consumption (Figure 5).

Fig 5. Combined cycle based on a PEM electrolyzer

Optimizing System Efficiency Early On

When designing energy systems that incorporate electrolyzers, it’s crucial to evaluate efficiency early on during the thermodynamic modeling stage. Using tools like AxSTREAM System Simulation allows a comprehensive look at how all the components interact, from flow dynamics and energy losses, to overall conversion efficiency. This approach supports the development of scientifically grounded decisions when designing and optimizing hydrogen energy systems.

The Next Steps for Electrolyzers

Electrolyzers are a key component of hydrogen energy systems, transforming electrical energy into a chemical form for long-term storage. This capability helps maintain a stable energy supply, build hydrogen reserves, and improve the overall efficiency and reliability of the system. By understanding how electrolyzers work and how they integrate into energy systems, we move one step closer to a future that’s powered by clean, sustainable fuel, and a greener world for the generations to come.

If you’d like to learn more about our research and developments in the area of electrolyzers and green hydrogen energy, we’d be happy to provide more information and discuss cleaner energy solutions for your projects. Contact us here: https://www.softinway.com/contact-us/

References

- https://doi.org/10.1016/j.ijhydene.2021.10.166

- https://doi.org/10.1016/j.ijhydene.2021.09.018

- https://doi.org/10.1016/j.energy.2023.128911

- https://doi.org/10.1016/j.rser.2025.116170

- https://doi.org/10.1016/j.rser.2025.116005

- https://doi.org/10.1016/j.rser.2025.116170

- https://doi.org/10.1016/j.jnlest.2021.100080

- https://doi.org/10.1016/j.ijhydene.2019.07.028

- https://doi.org/10.3390/en13184726

- PROSIMPLUS APPLICATION EXAMPLE. HYDROGEN PRODUCTION BY ELECTROLYSIS. Hydrogen production by electrolysis. – March 2024.

- A. Noring, K. Buchheit, and A.K.S. Iyengar, “Techno-Economic Analysis of Large-Scale Hydrogen Production from Solid Oxide Electrolysis Cell Systems,” National Energy Technology Laboratory, Pittsburgh, May 31, 2024.

"*" indicates required fields