Teamcenter PLM

Product Lifecycle Management for Engineering and Manufacturing

Teamcenter is a comprehensive product lifecycle management (PLM) platform that enables engineering and manufacturing organizations to manage product data, processes, and collaboration across the entire digital thread. As products become more complex and organizations become more distributed, disconnected systems and manual data management create version control issues, slow decision making, and increase program risk. Teamcenter eliminates these challenges by providing a centralized, secure environment for managing product information from concept through production and service.

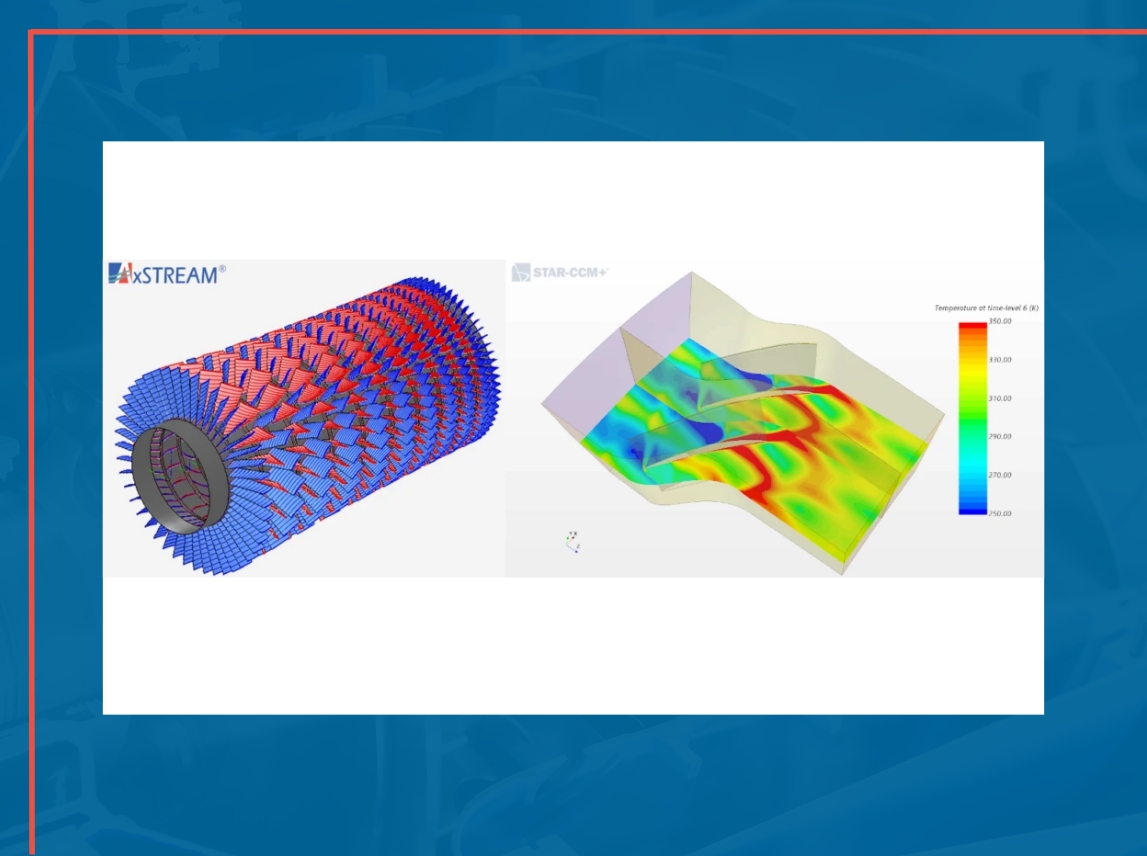

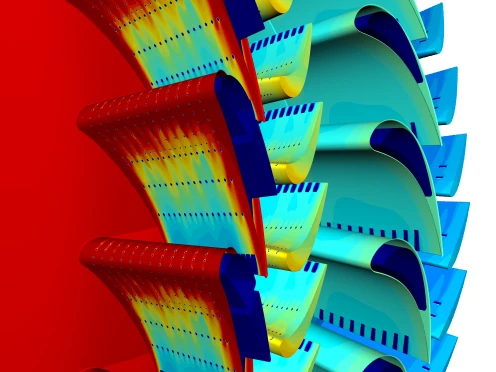

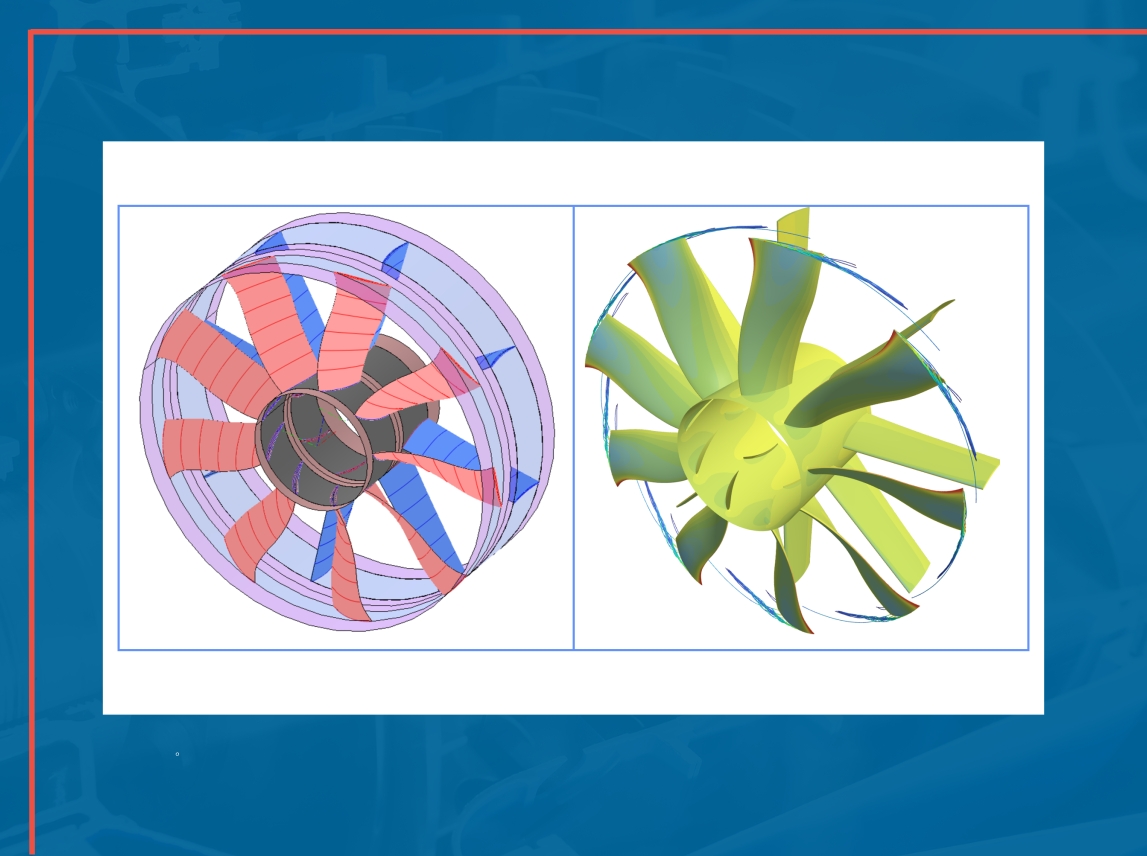

When leveraged with AxSTREAM, engineers gain a continuous digital thread that connects system simulation, turbomachinery design, rotor dynamics, optimization, CAD/CAM, and manufacturing data within a single governed PLM environment. This integration ensures design consistency, full traceability, and seamless collaboration across the entire product development lifecycle.

Teamcenter Benefits & Capabilities

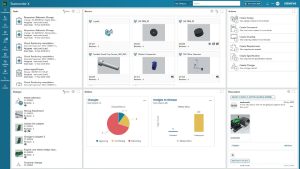

Product Data Management and Digital Thread

Benefits:

- Maintain a single, accurate library for all engineering and manufacturing data.

- Ensure full design traceability and configuration control across the entire product lifecycle.

- Eliminate costly errors caused by version confusion, disconnected files, and manual handoffs.

Capabilities:

- Enables centralized management of CAE, CAD, simulation, system and operational requirements, and manufacturing data in one secure PLM system.

- Full configuration, version, and change management to control product evolution across programs and variants.

- Establish and maintain a complete digital thread linking requirements, system models, AxSTREAM designs, CAD geometry, simulation, and manufacturing definitions.

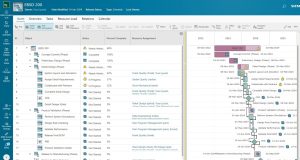

Process Management and Cross-Team Collaboration

Benefits:

- Streamline design change requests and approvals with full traceability and revision control.

- Improve collaboration across engineering disciplines, suppliers, and manufacturing teams.

- Ensure global teams work from the same validated data in real time.

Capabilities:

- Built-in workflow and change management tools to support engineering change requests (ECR), change orders (ECO), and formal review processes.

- Role-based access control and secure data sharing across internal teams, suppliers, and partners.

- Multi-disciplinary collaboration across mechanical, electrical, systems, manufacturing, and analysis teams within a unified platform.

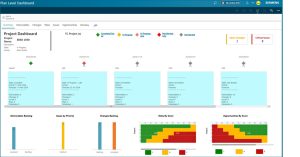

Systems Engineering, Manufacturing, and Program Control

Benefits:

- Align system-level requirements with detailed mechanical and manufacturing definitions.

- Improve program visibility, schedule control, and execution confidence.

- Reduce downstream manufacturing risk through early validation and controlled data handoff.

Capabilities:

- Trace requirements to system models, simulation results, and physical product definitions.

- Manage bills of material (EBOM, MBOM), manufacturing process plans, and production data within the same PLM environment.

- Program and portfolio management tools for tracking milestones, deliverables, risks, and product readiness.