SIMCENTER STAR-CCM+

Complete Multiphysics CFD Software for High-Fidelity Engineering

Simcenter STAR-CCM+ is a multiphysics simulation software built for engineers to model and analyze designs under the most realistic operating conditions. As designs grow more complex and development timelines continue to shrink, many teams are still forced to rely on disconnected, single-physics tools and manual workflows that slow iteration and increase risk. STAR-CCM+ overcomes these limitations with automated workflows and high-fidelity multiphysics simulation capabilities for fluid flow, heat transfer, and structural performance.

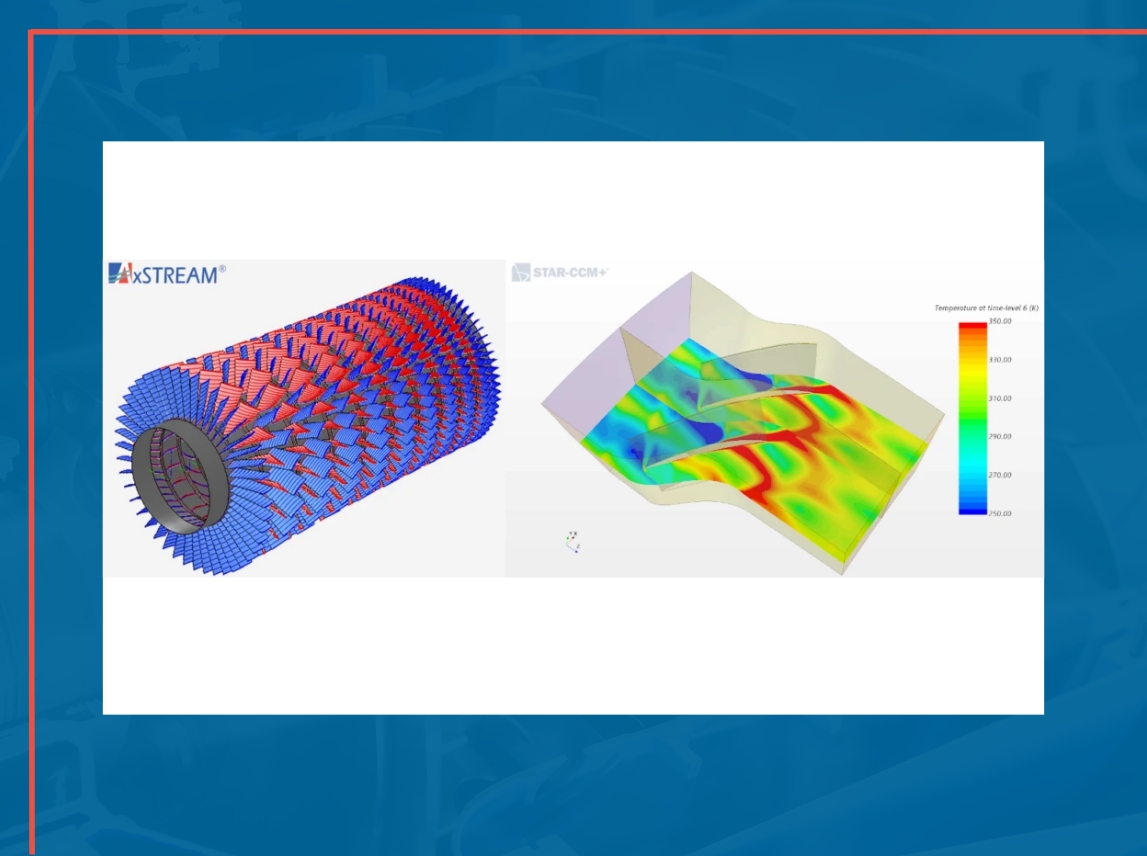

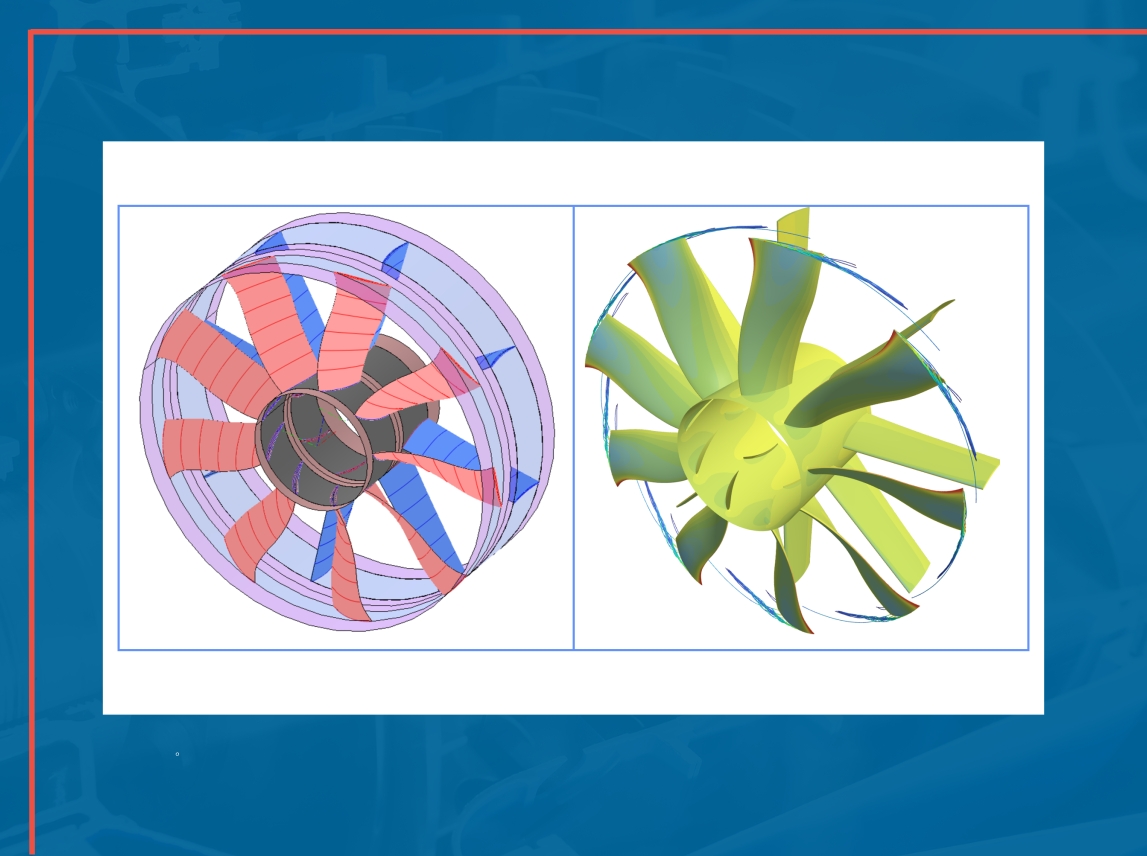

When paired with AxSTREAM, engineers gain a seamless workflow from preliminary design and full 3D geometry generation through detailed multiphysics validation in STAR-CCM+, enabling faster, more confident innovation in turbomachinery and thermal-fluid systems.

STAR-CCM+ Benefits & Capabilities

Geometry and Meshing

Benefits:

- Reduce simulation setup time when preparing complex geometries for turbomachinery, energy, and propulsion applications.

- Achieve reliable, high-fidelity results across intricate components and coupled multiphysics behavior.

- Iterate and optimize designs faster by minimizing manual cleanup and meshing rework.

Capabilities:

- Import, clean, and prepare intricate parts and assemblies for turbomachinery, propulsion, and energy applications.

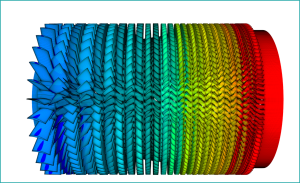

- Generate high-quality surface and volume meshes with automated workflows, specialized methods for turbomachinery components, and optimized multiphysics simulations.

- Maintain CAD-to-mesh associativity to keep simulation models synchronized with geometry updates and enable seamless handoff from AxSTREAM to STAR-CCM+.

Multiphysics Simulation

Benefits:

- Predict real-world system performance with confidence before physical testing begins.

- Accurately represent true operating conditions for rotating machinery, thermal systems, and multiphase flows to ensure prediction confidence and design outcomes.

- Optimize design performance while reducing development risk, cost, and iteration time.

Capabilities:

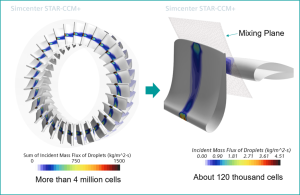

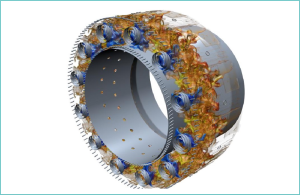

- Model coupled flow, heat transfer, turbulence, combustion, reacting species, phase change, and multiphase behavior in a single simulation framework.

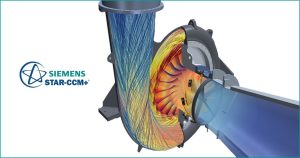

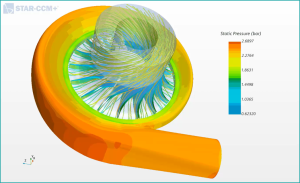

- Simulate rotating frames, sliding mesh interfaces, overset meshes, and complex motion for rotating machinery, with direct 3D validation of AxSTREAM turbomachinery designs.

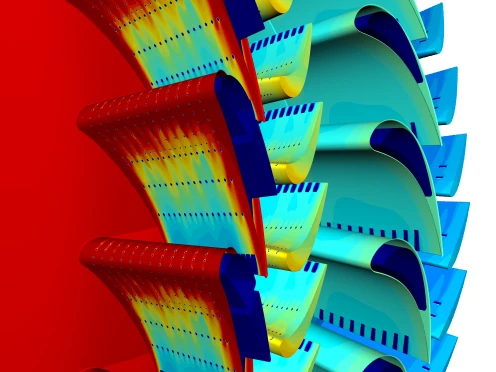

- Evaluate fluid solid interactions and thermal loading with fully coupled conjugate heat transfer (CHT) and fluid-structure interaction (FSI) capabilities.

- Solve steady and transient compressible turbulent flows with high numerical accuracy and adaptive mesh refinement in critical flow regions.

- Leverage GPU acceleration, HPC clusters, and cloud compute environments to reduce simulation turnaround times.

Optimization, Automation & Data Handling

Benefits:

- Accelerate design iteration and enhance product performance with automated workflows.

- Ensure consistency across the full development cycle.

- Improve collaboration and decision-making through intuitive data sharing tools.

Capabilities:

- Study design variations and performance sensitivities with integrated design exploration tools and refine geometry using flow-driven topology and shape optimization with support for additive manufacturing.

- Automate preprocessing, simulation setup, solver execution, and post processing, leveraging AxSTREAM alongside STAR-CCM+ for consistent design iteration.

- Visualize and share results using built-in post-processing tools and browser-based interactive viewers aligned with AxSTREAM outputs for efficient comparison of design and simulation data.