There has been a tremendous development in Computational Fluid Dynamics (CFD) in the last few decades along with the continuous enhancement of computing resources. CFD is now a very popular tool for all designers. However, if not used wisely, it can lead to the waste of significant engineering time as well as high costs. CFD not reached the state of replacing traditional analytical methods in the design process despite its rapid growth.

Let’s assume that you have been tasked with designing a new component from scratch. Would you be able to use CFD straight away? The answer is no, simply because there is no geometry available at this step. At the very beginning of designing a new component, a user needs a preliminary design tool which can quickly generate the design space based on specific requirements, boundary conditions and geometric constraints.

At this early stage, there is no point employing CFD because it could take months to generate the basics of the design space in this tool. Using CFD at this stage would be a waste of time and money not just for the designer, but also hardware. Assuming ownership of a cluster, the hourly rate of a CPU can be as low as 0.06$ and it can increase up to 0.2$ as the computing performance deteriorates within 5 years [1].

Once the preliminary design has been completed and a geometry is selected, the designer employs 1D/2D solvers to calculate the performance of the component under different operating conditions and to generate off-design performance maps. At this stage, CFD can be used to validate the solution against the 1D/2D methods first for the design point and then for few off-design conditions. Depending on the agreement between the results, the CFD may or may not be selected to be used to further evaluate the designs.

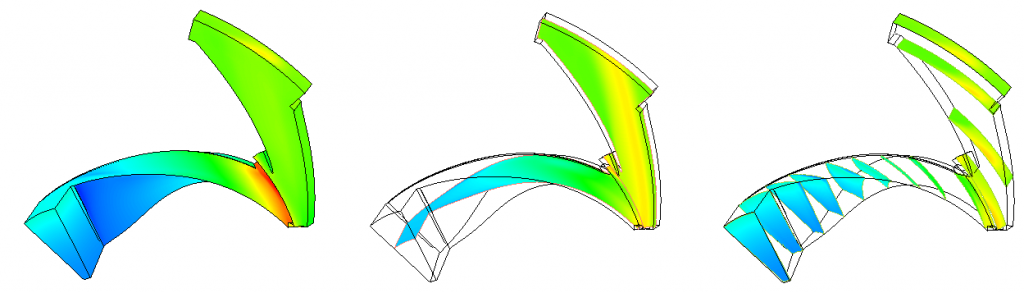

Another reason to use CFD is to study complex flowfields and get an in-depth understanding of the phenomena taking place in the flowpath. These results can be useful for further investigation of fluid-structure interactions in order to avoid unwanted vibrations and stability problems. Optimization of an existing turbomachine may also require the use of CFD coupled with Design of Experiment (DoE) approaches to generate more accurate macromodels and response surface which defines the characteristics of the given machine for the provided range of values and parameters.

Moreover, designers should exploit CFD as a tool to drive innovation when they deal with flow phenomena like separations, cavitation developments etc. For instance, flow control devices to suppress such phenomena have been studied. These phenomena can vary from trailing edge blowing for blade wake manipulation [2] to phased plasma actuators [3] and boundary layer suction technique to increase operating ranges of a turbomachine. However, in order to study such devices, complex geometries need to be generated. CFD is necessary to understand these geometries, which in turn need to be supported by experiments

To conclude, CFD is a powerful tool, but it needs to be used with great care because of time and cost implications. It can definitely help optimize existing machines and understand the flow physics of new designs, but designer cannot rely exclusively to CFD to create new machines. This could change in the next years along with further development of computing resources. Till then a combination of preliminary design tools, 1D/2D solvers and even experimental setups is essential. If you need some help to optimize your engineering activities and resources our experts are here to assist you. Feel free to drop a line at info@softinway.com for a short follow up chat, or meet our team at one of the following events: Turbo Expo, Paris Air Show, EUCASS.